After reviewing the information in your request form, a representative will contact you via your registered email address or phone number.

When we contact you, we will ask about your product specifications, manufacturing challenges, and technical concerns.

Have an idea or technology in mind?

Leave it to Endo Manufacturing!

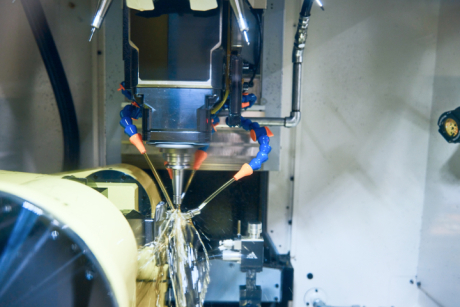

for our customers by making full use of the forging technology we have developed over the past 50 years since our founding,

and we have continued evolving our technology as needed.

With our many years of experience and extensive track record,

we help customers meet their needs and realize their ideas.