Manufacturing of parts with the top market share in seamless metal pipes for OA devices in Japan

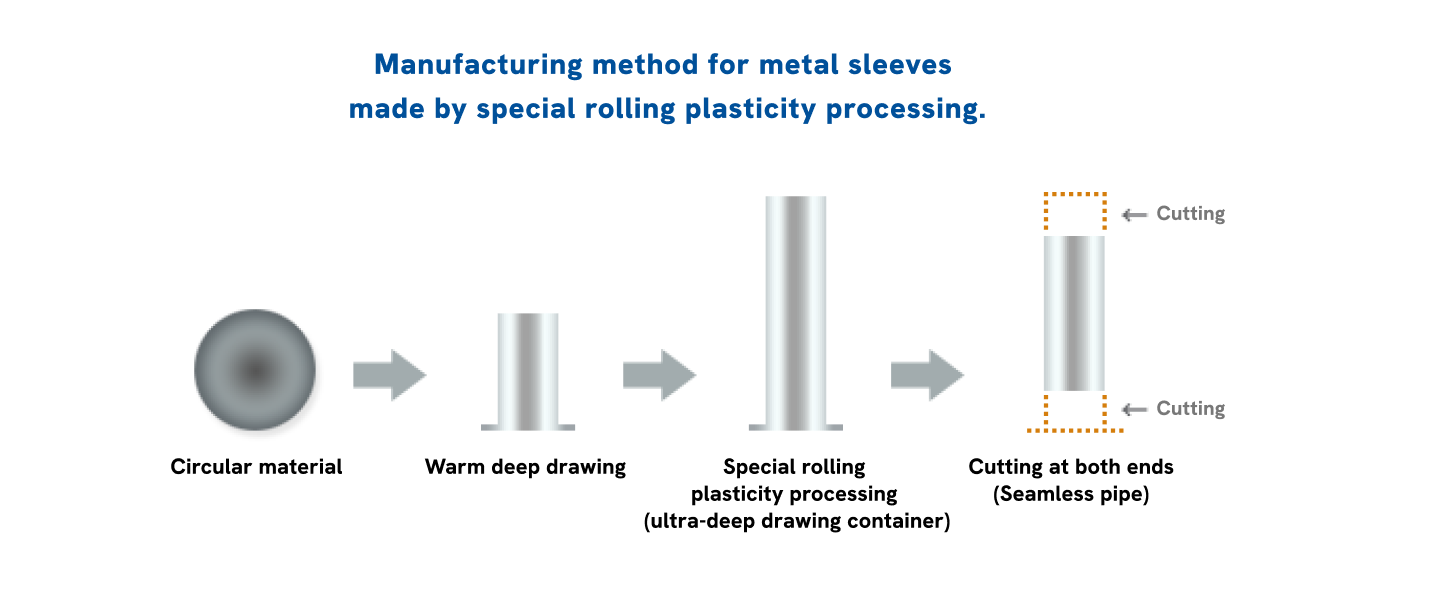

We manufacture a variety of parts utilizing “Metal Sleeve*,” our proprietary 10-µm ultra-thin seamless metal pipe.

Our products are especially popular in the OA device field, where they are used in fuser rollers and heating rollers, and we have gained the top share of the Japanese market for seamless metal pipes for OA devices. In addition to OA device parts and electrical devices, our products have recently drawn attention in fields requiring high precision and high strength, such as automobile parts, aircraft parts, medical device parts, motors, batteries, and electronic parts.

We continue to market our products based on how useful they are in the environmental industry and medical industry, and provide solid value with our unique technology.

Metal Sleeve is a unique technology that is the culmination of all of Endo Manufacturing’s metal plastic forming technologies.