Growth strategies

for the medical devices field,

to support an aging society

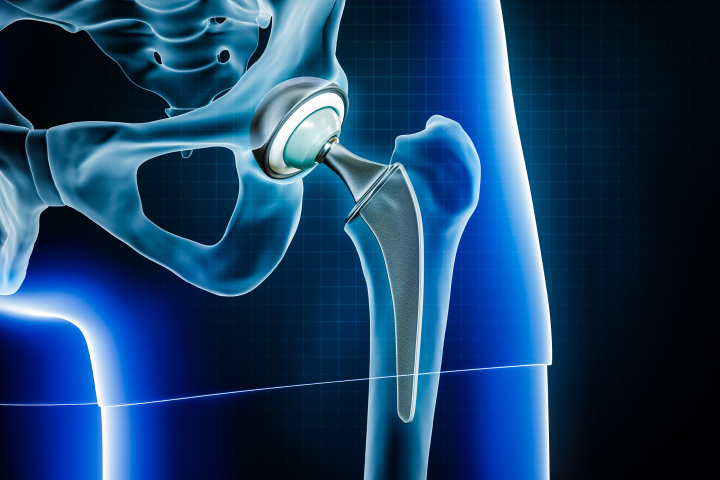

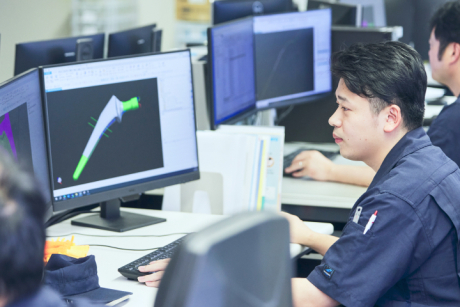

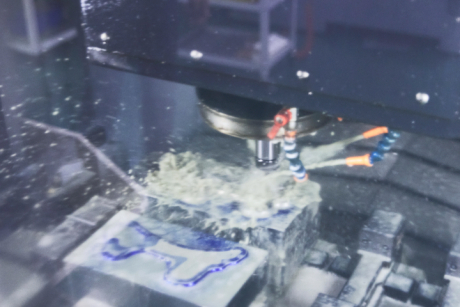

We manufacture medical devices (implants) such as artificial joints and bone-junction plates, utilizing our precision forging technology and processing technology for medical alloys (titanium alloys, cobalt-chromium alloys, and high-nitrogen stainless steel). Our integrated in-house system covers everything from CAD/CAM to inspection, allowing us to flexibly handle small-batch high-mix production with short lead time.

In 2011, we obtained ISO 13485 certification* and entered the medical device industry. Since then, we have earned the trust of companies active all over the world.

We will continue to promote research and development in anticipation of increasing demand from aging populations in the Asia region. The medical devices field is highly specialized, and we aim to achieve sustainable growth by promoting the kind of technological innovation that only Endo Manufacturing can achieve.

ISO 13485 (obtained by Medical Devices Department)