Manufacturing of parts that support the creation of automobile manufacturers around the world

In the forging field, based on the high-precision and high-strength hot forging technologies we have developed through manufacturing golf club heads, Endo Manufacturing provides integrated services covering everything from forged part development to mold fabrication and manufacturing for a wide range of industries, including two-wheeled vehicle and automobile parts such as engine gears and transmission gears, and agricultural machinery parts.

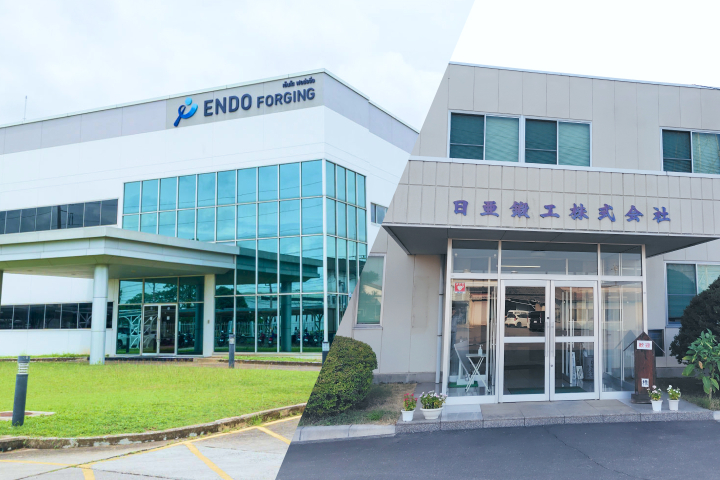

Our manufacturing base in Thailand, where automobile industry manufacturers from all over the world are concentrated, has allowed us to meet and respond to each and every expectation and request from automobile manufacturers in Japan as well as the U.S. and Europe. We are highly regarded for our extensive track record.

In 2025, we acquired as a subsidiary Nichia Forging Co., Ltd., which excels in the manufacturing of large forgings for turbine parts, construction machinery parts, and railroad parts that form the foundation of infrastructures. We will continue to challenge ourselves to create new value to meet diversifying needs by entering into markets for large forgings, machine tool parts, forged products for electrical appliances, and non-ferrous metal products.