We utilize the hot forging technology we have developed in manufacturing golf club heads in manufacturing parts for automobiles, two-wheeled vehicles, and agricultural machinery. We have established an integrated system covering everything from development to mold fabrication and manufacturing to meet the needs of global manufacturers. In 2025, we acquired Nichia Forging as a subsidiary and then expanded into manufacturing large forgings and non-ferrous metal products. We are taking on the challenge of creating new value in response to diversifying industries.

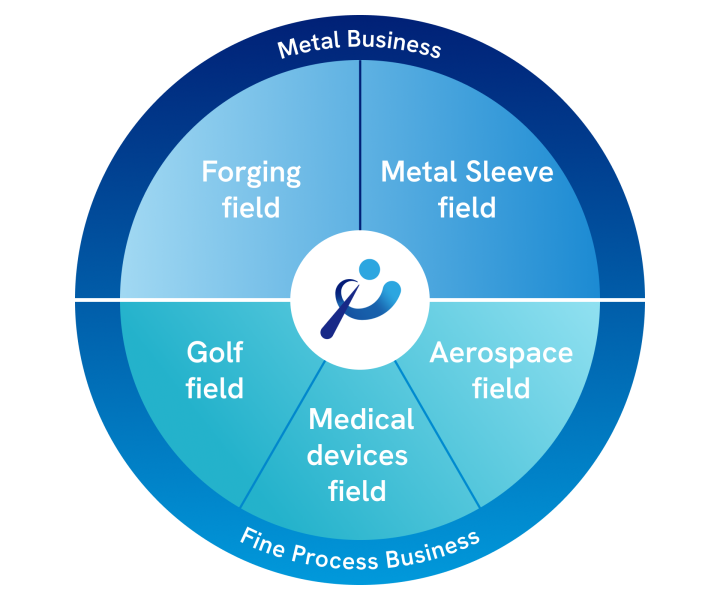

Endo Manufacturing has continued to grow in a wide range of fields including the automobile, sports,

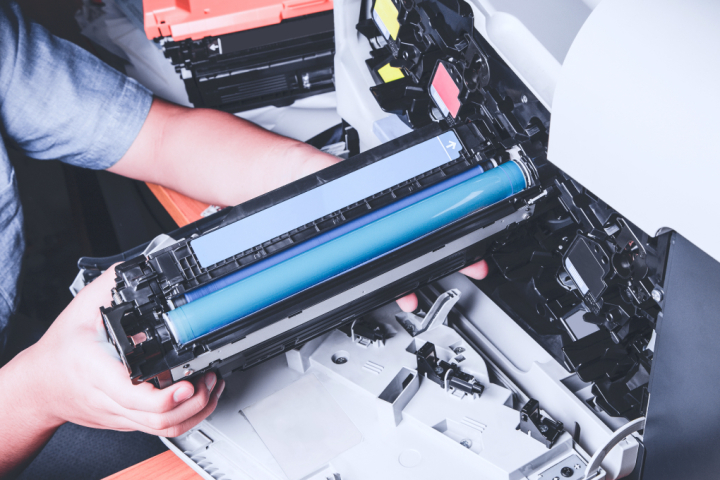

medical, aircraft, and electrical device fields, under our philosophy of “Creating a future without limits.”

We are committed toward solving social issues through advanced manufacturing,

and toward helping realize a sustainable future.

The products we provide help bring abundance to people and develop society,

and serve as foundations supporting daily life, industry, medicine, and culture.