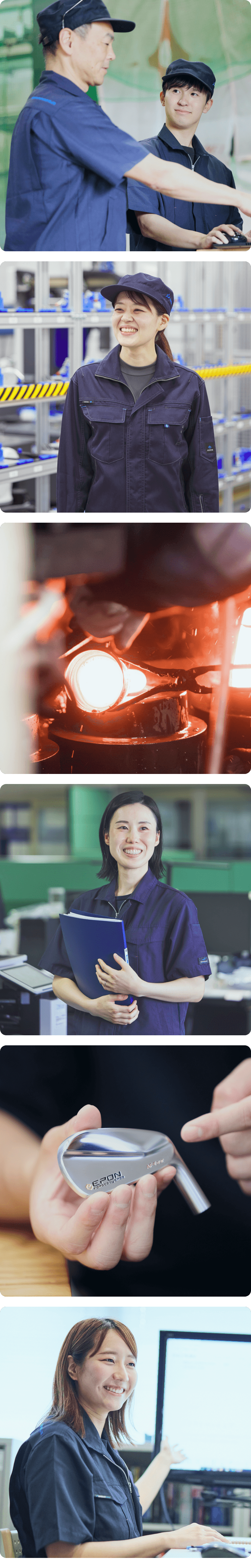

ENDO MESSAGE

Bringing the world products only Endo can provide.

All of our technology is developed together with our customers.

Based on our forging and metal plastic forming technologies, Endo Manufacturing offers one-of-a-kind value in a wide range of fields, including the golf, medical, aircraft, sports, electrical device, and automobile fields.

We work together with our customers through technical development, planning, and OEM supply in response to requests and consultations by world-renowned manufacturers.

We are highly regarded for our technical skills, insight, and creativity in creating product innovations with a deep understanding of the latent needs of the market.

This requires unrelenting effort.

Endo Manufacturing technology helps to keep the world moving and brings happiness to people, the earth, and the future.

We are working together with our customers to create a future without limits.

Our challenge will continue.